MoldMender

INCREASE PRODUCTIVITY & REDUCE COST

The Rocklin MoldMender Microwelder uses metallic ribbon, wire, paste or powder to repair molds and dies made of steel.

The Rocklin MoldMender Microwelder repairs plastic injection molds, rubber processing molds, and die casting molds and dies made of steel. Typical applications are parting lines, corners, edges, pin holes, scratches, machining errors, etc.

The repairs are produced by a low heat, non-arcing microwelding process. This produces a microweld with the least amount of heat, so shrink lines and other cosmetic defects are eliminated.

Microwelding a mold or die is as easy as placing metallic ribbon, wire, paste, or powder over the area to be repaired. Then simply roll the electrode over the area to permanently bond the welding material to the workpiece. No previous microwelding or mold / die repair experience is necessary!

MoldMender Short Video

MOLDMENDER MODELS

Rocklin MoldMender Microwelder weighs only 50 pounds and is very portable, allowing repairs to be performed anywhere in the shop, including mold repair in the injection molding machine.

No previous molding experience is required to operate the Rocklin MoldMender Microwelder. To place an order, simply fill out our online form or contact Rocklin Manufacturing Co. by phone or by email.

Rocklin MoldMender Microwelders have six low power selections and eight high power selections, which adjust the microweld pulse length to accommodate different microwelding situations. Also, the microweld speed (number of microwelds per second) has six selections.

Highlighted Features

- Push Button Controls for exact machine settings

- Six Low Power settings for delicate repairs

- Eight High Power settings for faster and heavier repairs

- Variable Microweld Speed control for various job demands

- Automatic Indicator Lights for assistance in machine settings

- Audio Microweld Indicator for ease of operation

- Heavy Duty Rotary Hand Piece, Cables and Copper Ground Plate

- 100% Solid State electronics for reliable operation

- Employs a non-capacitive, resistance microwelding process for more dependable results

- Made in USA by an established company providing prompt service

Specifications

- Power Requirements

110 – 120 volts

(220 – 240 volt models available)

- Dimensions

W x L x H: 10″ x 12″ x 14″

(255 mm x 305 mm x 355 mm)

- Shipping Weight

50 lbs. (22.7 kg.)

Rocklin MoldMender Microwelders come complete with power cord, foot switch and cable, metal scissors, electrode holder and cable, ground plate and cable, small electrode, large electrode, repair materials (choice of 4 metallic ribbons, 2 metallic wires and 1 metallic paste), and instruction manual.

APPLICATIONS

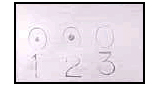

The Rocklin MoldMender Micro Welder can be used in a variety of applications, from repairing pin holes to fixing parting edges, using a simple micro weld process, easily mastered in just minutes.

After a mold or die has been run for an extended period of time, a nick, a scratch, or some other imperfection often appears in the molding area. Or, perhaps the parting line starts to wear, and the mold or die must be repaired. It would be impractical to attempt these small repairs by TIG welding; however, it is possible to micro weld them using the Rocklin MoldMender Micro Welding Process.

| TYPICAL APPLICATIONS | |

Repair mold and die |

Repair mold and die |

Repair mold and die |

Make mold and die |

Install mold and die shims.

|

Repair mold and die |

Mold and die pin hole |

Mold and die parting line |

MoldMender Short Clip (15 seconds)

MoldMender Full Video (11 minutes)

Please contact us to learn more about this valuable tool, including pricing, delivery and support.

.gif)